Metal roofing cutters are essential tools designed specifically to cut through tough metal roofing materials cleanly and efficiently. They allow professionals and DIY enthusiasts to make precise cuts without damaging the metal or causing jagged edges.

Choosing the right metal roofing cutter depends on the type of metal, thickness, and the specific project requirements. Understanding these factors helps users select a tool that saves time and improves the quality of the roofing installation.

Types Of Metal Roofing Cutters

Metal roofing cutters vary by power source, cutting method, and precision. Each type suits different materials and thicknesses, affecting ease of use and finish quality. Understanding these options helps choose the right tool for specific roofing tasks.

Hand Shears And Snips

Hand shears and snips are manual cutting tools designed for thin metal sheets. They are best for straight cuts or gentle curves in lighter gauge roofing materials like aluminum or steel.

These tools come in three main types: straight-cut, left-cut, and right-cut snips. Straight-cut snips produce clean straight lines, while left and right-cut snips are used to follow curved patterns without damaging the metal’s edge.

They require physical effort but offer fine control. Hand shears are portable, don’t need power, and produce minimal noise. However, they can be time-consuming for larger jobs or thicker metals.

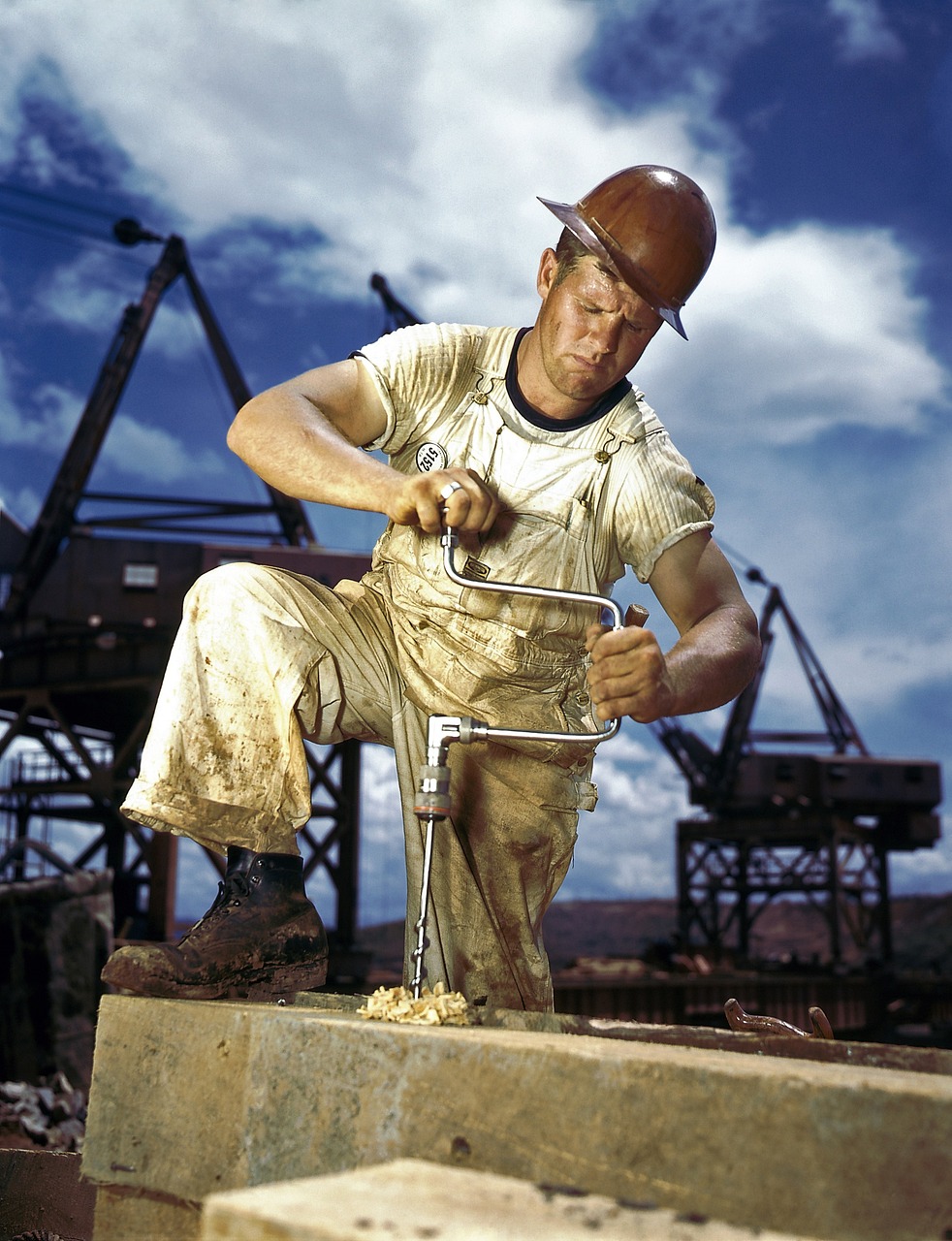

Electric And Power Tools

Electric and power tools, such as metal shears, circular saws with metal blades, and angle grinders, offer faster cutting for thicker or longer metal roofing panels. They reduce manual labor significantly.

These tools provide smooth, more precise cuts and are suitable for thicker gauge metals (up to 26 or 24 gauge). Some models have variable speed controls to adjust for different metals.

Power cutters require a power source, and safety gear is necessary due to noise and sparks. They are ideal for professional or frequent use but less practical for small, quick tasks.

Nibblers And Specialty Blades

Nibblers remove metal by punch-and-die action, creating precise cuts with less distortion. They work well on complex shapes and tight curves without bending or warping the material.

Specialty blades for metal cutting include carbide-tipped or abrasive options used with saws. These blades accommodate harder metals and thicker panels, extending tool life.

Nibblers and specialty blades reduce metal fatigue and offer cleaner edges compared to shears or grinders. They are preferred for detailed work or when maintaining metal integrity is crucial.

Choosing The Right Metal Roofing Cutter

Selecting a metal roofing cutter depends on factors like cutting precision, ease of use, and product longevity. Understanding these aspects helps in finding a tool that suits specific roofing needs and ensures safety during operation.

Cutting Efficiency And Precision

The cutter’s blade quality directly affects cutting speed and smoothness. High-carbon steel or tungsten blades maintain sharpness longer, reducing effort and preventing jagged edges.

Shear cutters and nibbler tools offer different levels of precision; shears provide straight cuts while nibblers excel at curves and complex shapes. Choosing the right type depends on the roof’s design requirements.

Blade size and power source—manual, electric, or pneumatic—also influence efficiency. Electric models streamline repetitive cuts, whereas manual cutters may suffice for small or occasional work. The balance of power and control is key.

Safety And Handling Considerations

Ergonomic design reduces fatigue and the risk of accidents during extended use. Handles with rubber grips and well-balanced weight distribution help maintain secure control.

Safety features such as blade guards and locking mechanisms prevent unintended injuries. Users should pick cutters that comply with recognized safety standards.

Protective equipment, including gloves and eye protection, remains essential regardless of cutter type. Users must also understand proper cutting techniques to avoid metal kickback and sharp scrap.

Maintenance And Durability

Regular blade sharpening or replacement is necessary to sustain cutting quality. Models with easily accessible blades simplify maintenance tasks.

Rust-resistant coatings and corrosion-proof materials extend the tool’s lifespan, especially when used outdoors or in humid environments.

Storing the cutter in a dry, secure place prevents damage. Durable cutters combine solid construction with low upkeep, saving time and money over the long term.

Leave a Reply